Comfort You Can Count On

TruComfort Heating and Cooling Of Southington, CT

Proudly serving Southington, Cheshire, Plainville, Bristol, Avon, Farmington, West Hartford, and beyond, TruComfort Heating and Cooling delivers expert heating and cooling solutions with reliability and care. Whether you need installation, repairs, or maintenance, our team ensures your home stays comfortable year-round. Trust us for quality service, honest pricing, and exceptional workmanship in your community!

About TruComfort Heating and Cooling

At TruComfort Heating and Cooling, we’re more than just a heating and cooling company—we’re a local, family-owned business committed to keeping our community comfortable. With over 20 years of experience in the HVAC industry, we take pride in delivering personalized service, honest advice, and quality workmanship to every customer.

Learn More

As a family-run business, we understand the importance of maintaining a comfortable home throughout the year. Whether you need routine maintenance, emergency repairs, or a system upgrade, our certified technicians treat every home as if it were their own—with care, respect, and attention to detail.

Our dedication to customer satisfaction and community values sets us apart. When you choose TruComfort Heating and Cooling, you’re not just a client—you’re part of the family. Let us be your trusted partner for all your heating, cooling, and water heater needs, helping you stay comfortable in every season.

Our heating and Cooling Services

At

TruComfort Heating & Cooling, we provide expert

heating installation, repair, and

maintenance

as well as

cooling system services

in Southington, CT. Our team works on all major

HVAC systems, delivering reliable comfort,

better energy efficiency, and long-lasting

performance to keep your home running at its

best year-round.

Heating Services

Stay warm with our high-efficiency furnaces, heat pumps, and boilers. From installation to seasonal tune-ups and emergency repairs, we keep your system running smoothly.

Air Conditioning Services

Beat the heat with our reliable AC solutions. We offer professional installations, fast repairs, and energy-efficient upgrades to maximize cooling comfort.

Indoor Air Quality Services

Breathe cleaner air with our purification systems, humidity control, and ventilation improvements. Our solutions enhance indoor air quality for a healthier home.

Ductless Systems

Enjoy flexible comfort with high-efficiency ductless systems. Perfect for any space, these energy-saving solutions provide customizable temperature control.

Water Heaters

Ensure a steady hot water supply with our expert water heater services. We install and replace gas, electric, tankless, and hybrid systems with same-day availability

Heating System Inspection

Table of Contents

Who to Call for a Heating Inspection

What Is An HVAC Home Inspection?

HVAC home inspection outclasses standard home inspection routines by delivering a focused, technical evaluation of a property's heating and cooling system. Carried out by certified HVAC professionals, it's not just a checkbox exercise for real estate deals. Instead, the process involves meticulously examining mechanical components, testing operational safety, and evaluating energy performance. All core elements--air filters, ducts, coils, thermostats, burners, and wiring--undergo detailed inspection. Outcomes are measured in system safety, efficiency, and real-world operational lifespan, supported by clear, data-driven reporting. No general home inspector achieves this level of insight, making independent HVAC inspection non-negotiable for serious Connecticut homeowners.

Inspection Benefits For Homeowners

Routine heating system inspection does more than prevent carbon monoxide tragedies--it uncovers hidden efficiency losses, diagnoses undetectable faults before full breakdown, and transforms the gamble of winter comfort into peace of mind. The safety impact is unassailable; risk of CO exposure plummets with verified system performance (EPA). Efficiency improvements from tune-ups can shave double-digit percentages off annual energy costs. Most critical, professional inspection provides a transparent record that protects equipment warranties and resale value. Homeowners leveraging TruComfort's multi-tier Comfort Care Maintenance Plans secure priority response, regular discounts, and cost control not available to the uninitiated. As energy prices rise and code compliance sharpens, skipping annual inspection sacrifices more than comfort.

Heating System Basics

Core Heating Components

Too many homeowners view their heating system as a monolithic box in the basement. Reality: every system consists of discrete, failure-prone components--each demanding focused attention during inspection.

- Furnace: Burner, heat exchanger, blower, controls, and filter. Inspectors check for heat exchanger cracks, burner condition, ignition reliability, filter obstructions, and airflow.

- Boiler: Burner unit, heat exchanger, pump, valves, pressure controls, and expansion tank. Disaster usually begins with scale buildup, leaking valves, or pressure mismanagement.

- Heat Pump: Compressor, reversing valve, coils (indoor/outdoor), and controls. Refrigerant leaks or electrical issues undermine performance fastest.

- Ducts & Vents: Inspectors search for leaks, insulation gaps, and blockages that slash delivered efficiency.

- Thermostats and Controls: Verified for accuracy and responsiveness. Faulty thermostats waste hundreds in annual heating costs.

Inspectors never accept visible condition alone--they test and validate each function.

Common System Types

Connecticut homes often combine dated boilers, modern forced-air furnaces, or split heat pumps--each requiring distinct inspection focus:

- Forced-Air Furnaces: These systems rely on burners, heat exchangers, and blowers. Inspection targets ignition, combustion chamber condition, filter status, CO leak risks, and airflow disruptions. Dirty filters and worn belts dominate failure stats.

- Boilers (Hydronic Systems): The focus lands on pressure control, burner operation, leak detection, and evidence of corrosion or scale. Undetected leaks or sediment in the exchangers devastate performance.

- Heat Pumps/Ductless Units: Key inspection points include refrigerant line integrity, reversing valve function, coil cleanliness, and defrost control. Low refrigerant or frozen coils will cripple efficiency.

Absolute fact: Over 70% of emergency heating repairs in Connecticut stem from neglected inspection of these core components.

Common Heating System Comparison:

System Type Primary Components Typical Inspection Focus Common Issues| Furnace | Burner, heat exchanger, blower, filter | Heat exchanger cracks, CO risk, airflow | Dirty filters, worn belts, ignitor failure |

| Boiler | Heat exchanger, pump, controls | Leaks, pressure, corrosion | Scale buildup, leaking valves, pump failure |

| Heat Pump | Compressor, reversing valve, coils | Refrigerant leaks, defrost operation, electrical | Low refrigerant, frozen coils, compressor wear |

Inspection Components Explained

Visual And Operational Checks

Inspectors never gamble on guesswork--they initiate the process with exhaustive visual checks: cabinet inspection, venting evaluation, filter examination, burner and ignition review, belt integrity check, and wiring condition survey. Each element receives objective documentation. Operational tests move inspection from theory to certainty. Technicians run full start/stop cycles, observe burner flame stability, measure airflow output, and digitally calibrate thermostats. Faults become indisputable when quantified. Homeowners lured by low-cost, superficial inspections simply subsidize bigger problems down the line. The only way to secure system longevity is to insist on this depth of operational validation every visit. Neglect sabotages efficiency and voids warranties.

Safety Testing And Diagnostics

Only advanced diagnostics prevent disaster. This includes combustion analysis (gauging flue gases and efficiency), carbon monoxide (CO) detection using professional-grade meters, pressure integrity checks, and complete control circuit validation. Every test uses purpose-built instruments, not just technician experience. The EPA insists on direct CO measurement as undetectable leaks kill without warning. Connecticut data is clear: failure to conduct these tests triples emergency hazard calls each winter. Technicians trained at TruComfort equip every inspection with validated checklists because they refuse to put revenue above real safety for their customers.

Inspection Test Comparison:

Test Scope Purpose When To Request| Visual Inspection | Exterior/interior components, ducts, vents | Identify visible wear, leaks, corrosion | Every inspection visit |

| Combustion Analysis | Flue gases, efficiency, CO levels (combustion units) | Check safety, combustion efficiency | If age, odd smells, low efficiency |

| Carbon Monoxide Testing | CO meter readings around appliance/home | Detect unsafe CO, leaks | If venting issues or symptoms |

Homeowner Inspection Checklist

Preparing For A Professional Visit

Inspection success for homeowners starts before the technician arrives--clearing access around equipment, noting suspicious odors or noises, recording setbacks in thermostat behavior, and collecting any service documentation. Never underestimate the value of preparing high-traffic areas for technician movement. TruComfort sets expectations for every Heating Service Call: customers get upfront explanations, diagnostic analysis, and detailed reporting. Prepared clients speed up troubleshooting and benefit from sharper insights every time.

Furnace Inspection Checklist

Practical steps for homeowners:

- Replace air filter--never wait for a technician. Clogged filters devastate performance.

- Inspect around furnace for water, soot, or fuel leaks

- Observe pilot or electronic ignition function

- Ensure vent/flue pipes are clear and unobstructed

- Test thermostat settings and observe system response

- Listen for odd noises during operation

Professional inspection dives further, adding combustion testing, electronic diagnostic scans, CO monitoring, and full electrical evaluation.

A homeowner's guide to preparing for and understanding HVAC inspections.

Homeowner vs Professional Checklist:

Task Homeowner Technician Reason| Filter Replacement | Yes | Verify type | Improves airflow, efficiency |

| Combustion Testing | No | Yes | Safety, CO risk, warranty status |

| Visual Leak Check | Yes | Yes, advanced diagnostics | Prevent damage and failures |

Expanded Diagnostic Options

What Standard Inspections Exclude

Standard HVAC inspections deliberately exclude full system disassembly, any destructive testing, comprehensive indoor air quality (IAQ) assessments, refrigerant recovery or recharge, and detailed duct leakage testing. These are advanced diagnostics that require specialized training, equipment, and scheduling. Homeowners who expect a single service call to magically produce "total clarity" on every aspect of their HVAC system are falling for a myth. Only expanded tests go this deep, but they are never bundled in basic tune-ups or service visits.

When To Request Expanded Tests

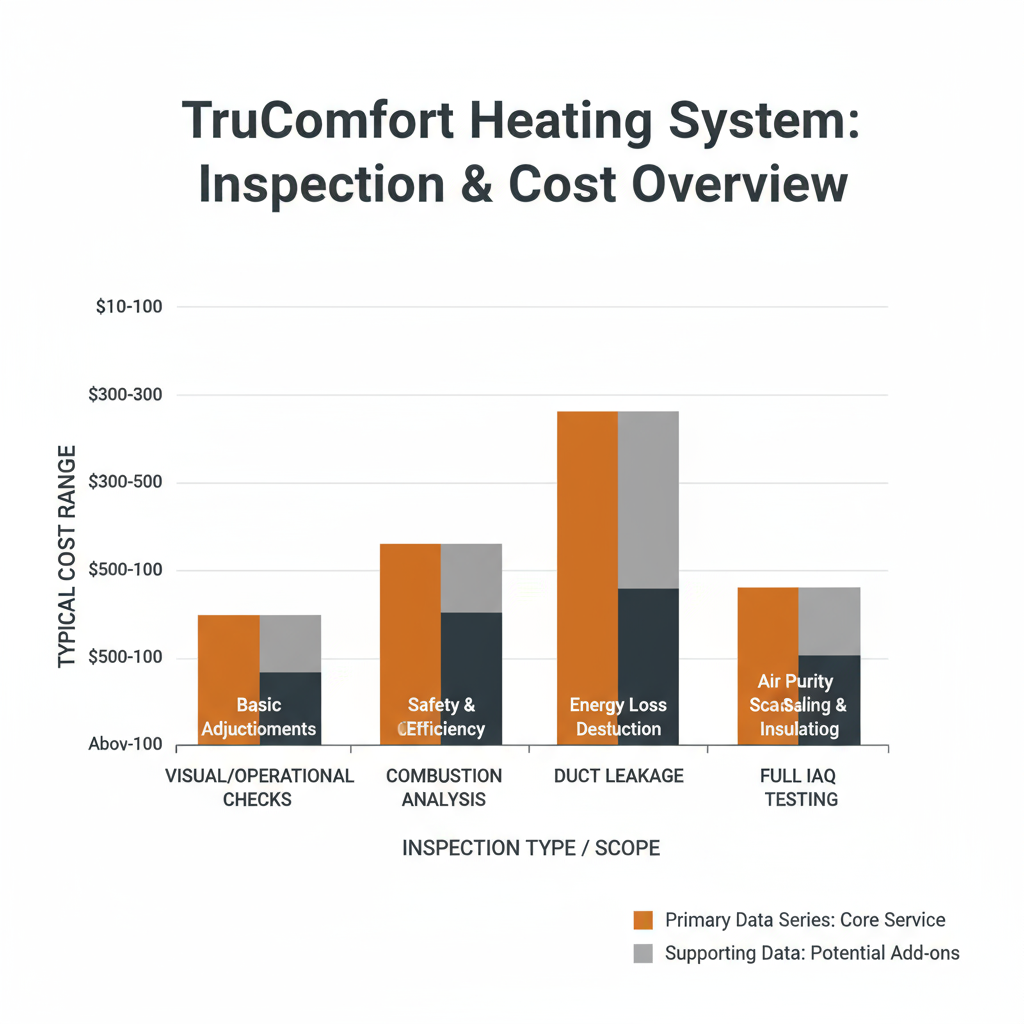

Expanded diagnostics are non-negotiable when efficiency steeply drops, unexplained odors arise, or utility bills spike without cause. Combustion analysis, duct blaster testing, refrigerant leak checking, and IAQ monitoring become critical in these situations. Most homeowners grossly underestimate their exposure to hidden hazards until extensive diagnostics reveal the truth. These services do carry extra cost: combustion analysis ($75-$200), duct testing ($300-$600). It's a fraction of the cost required to remediate advanced system failure or health complications.

TruComfort inspection types, scope, and cost ranges data visualization

Standard vs Expanded Inspection:

Service Standard Inspection Expanded Diagnostic Typical Cost Range| Visual/Operational Check | Yes | N/A | Included in service |

| Combustion Analysis | Optional | Required | $75 to $200 |

| Duct Leakage Test | No | Yes, specialized equipment needed | $300 to $600 |

Common Inspection Questions

-

What is an HVAC home inspection?

A specialized, detailed process by licensed HVAC professionals that goes far beyond basic home inspection--focusing exclusively on mechanical safety, efficiency, and component longevity. -

What does a home inspector look at for heating equipment?

Certified technicians examine filters, burners, exchangers, wiring, ducts, venting, ignition, and electronics using targeted tests--not guesswork. -

What is the purpose of a heating system inspection?

To guarantee operational safety, maximize fuel efficiency, protect against hazard, and extend the functional lifespan of all major components. -

Why are HVAC home inspections essential?

They expose costly hidden issues, lower energy waste, enforce warranty coverage, and reduce the chances of emergency breakdown and CO exposure. -

What is excluded from a standard HVAC inspection?

Destructive testing, deep IAQ analysis, full system disassembly, refrigerant recovery, and complete duct leakage assessment all require additional diagnostics.

After The Inspection

Next Steps For Homeowners

Smart homeowners treat a completed inspection as a launchpad--not a finish line. Insist on reviewing the full technician report, address any recommended repairs promptly, and compare maintenance plan options. Top performers lock in recurring service with Furnace Cleaning or enroll early in annual maintenance plans to preserve efficiency. Monitor digital CO alarms and indoor air quality data post-visit. Don't wait--HVAC Repair is most effective when problems are addressed proactively, not reactively. Schedule follow-up or replacement appointments with credentialed providers who deliver transparent pricing, certified work, and documented results. Book your next TruComfort inspection or repair today.

Resources

We welcome your comments!

Our Mission

Our mission is to provide reliable, energy-efficient heating and cooling solutions that ensure the comfort and safety of our customers. We are committed to delivering exceptional service with integrity, innovation, and a focus on quality workmanship. Our goal is to build long-lasting relationships with our customers by exceeding their expectations and enhancing the comfort of their homes all while maintaining a commitment to sustainability and community responsibility.

Our Value

We are dedicated to delivering exceptional service through honesty, integrity, and professionalism. Our values center on quality craftsmanship, customer satisfaction, and continuous improvement. We prioritize safety, reliability, and respect in every interaction, ensuring that every customer feels valued and every job is completed to the highest standards. We embrace innovation and sustainability, striving to provide energy-efficient solutions that enhance comfort and reduce environmental impact. Our team is committed to fostering trust and building lasting relationships with our customers and community.

Comfort Care Maintenance Plans

Protect your HVAC investment and enjoy peace of mind with our Comfort Care Maintenance Plans. We offer a plan for every budget and situation, designed to keep your system running at peak performance year-round. Regular maintenance not only extends the life of your equipment but also improves energy efficiency and prevents unexpected breakdowns.

Elite Plan

Full system cleaning added benefits, including priority service and discounts on repairs.

Essential Plan

Ideal for basic, routine check to keep your system running smoothly.

Elite Winter Plan

Tailored maintenance focused on your heating system to ensure warmth and reliability through the colder months.

Elite Summer Plan

Specialized maintenance for your cooling system to keep you cool and comfortable during the hottest months.